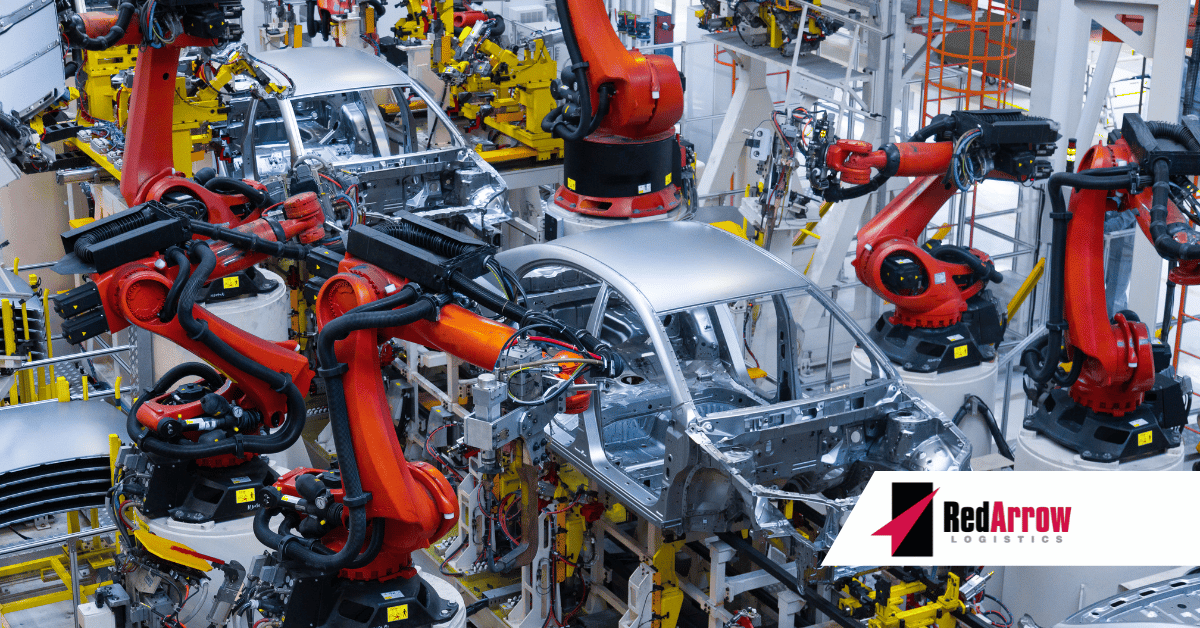

In today’s dynamic business landscape, successful operations rely on the seamless integration of various components within the supply chain. Among these, the collaboration between manufacturing and logistics stands out as a pivotal relationship that can make or break an organization’s efficiency and profitability. This synergy not only streamlines processes but also unlocks a multitude of benefits that can give companies a competitive edge in the market.

1. Optimized Production Planning

Collaboration between manufacturing and logistics enables a synchronized approach to production planning. By sharing real-time data on inventory levels, order volumes, and production schedules, both teams can align their efforts to ensure that manufacturing keeps pace with demand, eliminating unnecessary stockpiles or shortages. This, in turn, results in cost savings and improved customer satisfaction.

2. Reduced Lead Times

A harmonized manufacturing-logistics relationship significantly reduces lead times. Coordinated planning allows for just-in-time manufacturing, which minimizes storage costs and the risk of obsolete inventory. This agile approach not only enhances responsiveness to market fluctuations but also allows companies to allocate resources more efficiently.

3. Enhanced Quality Control

Clear communication and collaboration between manufacturing and logistics teams are instrumental in maintaining and improving product quality. A tight feedback loop ensures that any issues arising during production or transportation are addressed promptly. This proactive approach reduces the likelihood of defects, ultimately leading to higher customer satisfaction and loyalty.

4. Cost Efficiency and Resource Optimization

Collaboration fosters a culture of cost-consciousness across the entire supply chain. By working together, manufacturing and logistics teams can identify areas for potential cost savings, such as optimizing transportation routes, minimizing excess packaging, and reducing energy consumption. These efficiencies directly contribute to the bottom line.

5. Innovative Problem Solving

When manufacturing and logistics teams collaborate effectively, they bring diverse skill sets and perspectives to the table. This cross-functional approach fosters innovation and problem-solving. Together, they can develop creative solutions to challenges that may not be apparent when working in silos.

6. Risk Mitigation and Contingency Planning

In an unpredictable global market, risk management is paramount. A collaborative approach allows manufacturing and logistics teams to jointly assess potential risks and develop contingency plans. Whether it’s geopolitical events, natural disasters, or supply chain disruptions, this proactive stance helps companies navigate uncertainties and maintain business continuity.

7. Data-Driven Decision Making

Effective collaboration hinges on the exchange of accurate and timely information. Leveraging data analytics and shared platforms, manufacturing and logistics teams can make informed decisions based on real-time insights. This data-driven approach empowers both sides to optimize processes, improve forecasting, and adapt quickly to changing market conditions.

Conclusion

In today’s hyper-competitive business environment, the value of collaboration between manufacturing and logistics cannot be overstated. This synergistic partnership not only optimizes production processes but also drives cost efficiencies, enhances product quality, and fosters innovation. By working together, these critical components of the supply chain create a powerful engine that propels companies to new heights of success.

Your Trusted Partner

At Red Arrow Logistics, we understand the vital role that collaboration plays in achieving operational excellence. Through our integrated approach, we facilitate seamless coordination between manufacturing and logistics, unlocking a world of opportunities for your business. Contact us today to discover how we can help you leverage the full potential of this dynamic partnership.

Red Arrow offers the scale and scope of services including air, ocean, and ground transportation to meet the budget and schedule requirements of the largest and smallest companies alike. If we can be of assistance, please email us at info@redarrowlogistics.com or give us a call at 425-747-7914.